Detail Drawing

Price 249 INR/ Square Foot

Detail Drawing Specification

- Dimension

- 80 x 50 x 3 mm

- Manufacture Process

- Laser Cutting

- Material

- Mild Steel

- Thickness

- 3 mm

- Color

- Silver

- Weight

- Approx. 120 grams

- Application

- Fabrication/Assembly

- Tolerance

- ±0.1 mm

- Surface Roughness

- Ra 1.6 µm

- Finish

- Zinc Plated

- Drawing Type

- 2D CAD

About Detail Drawing

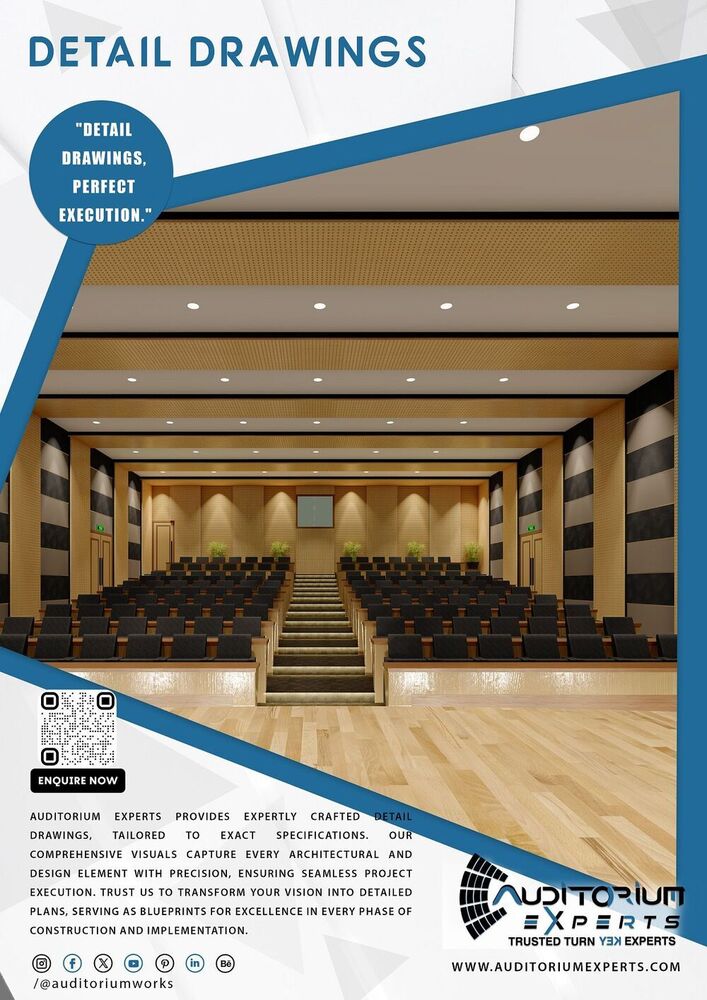

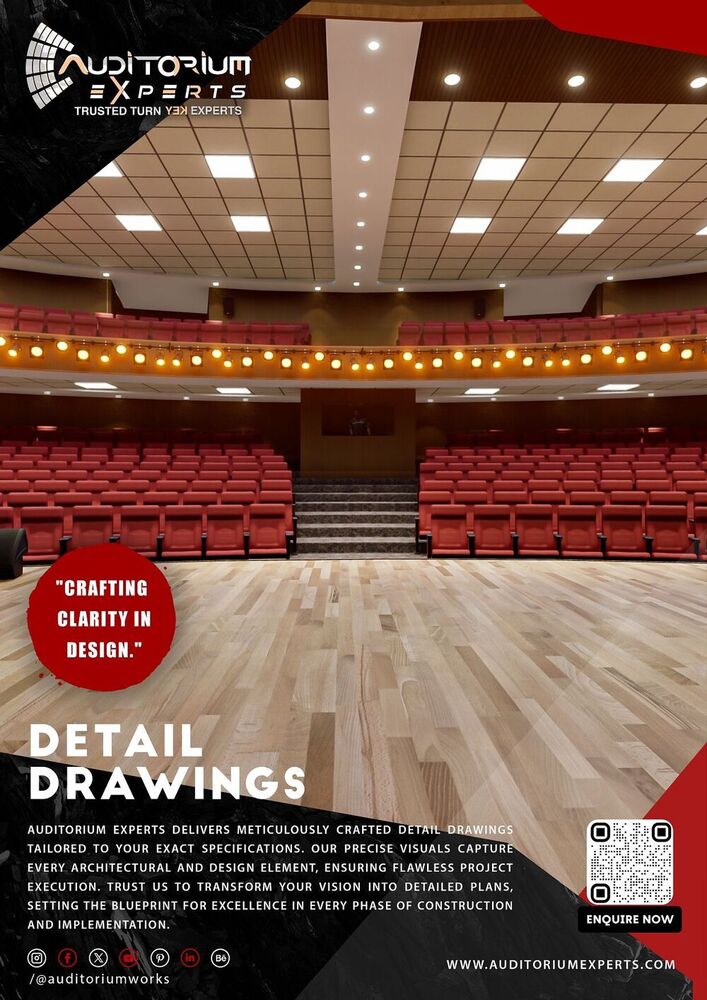

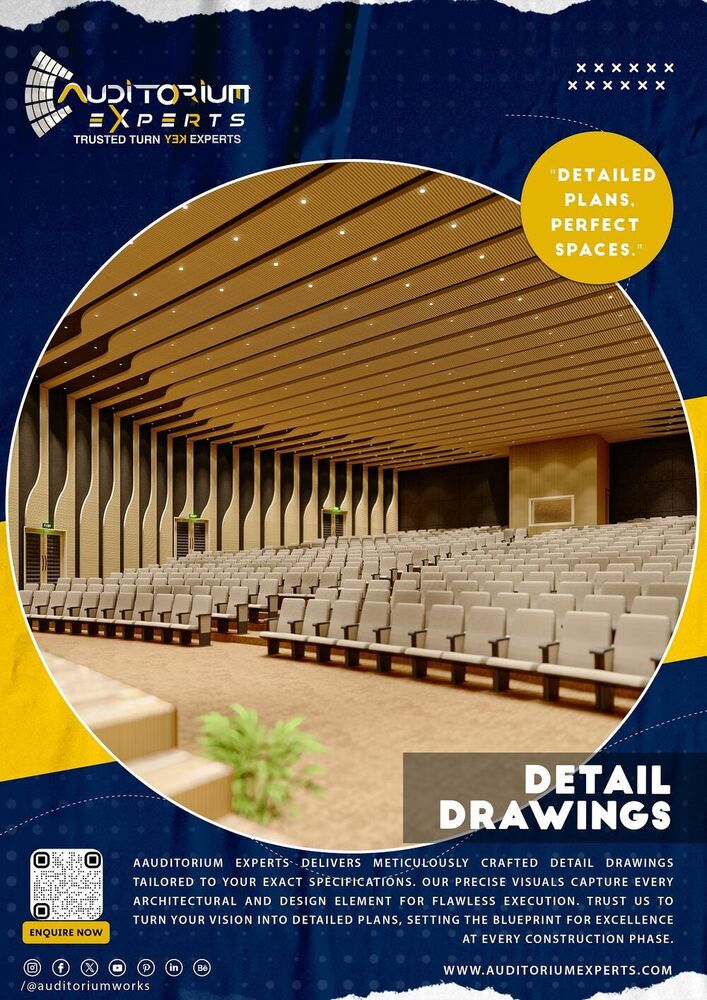

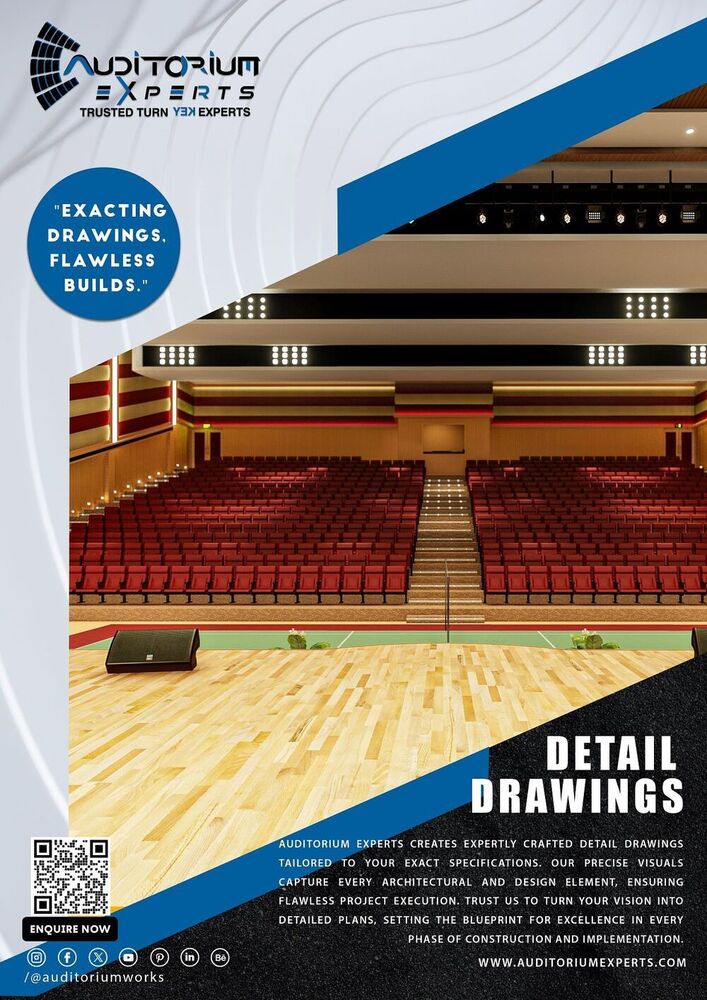

Precision in Design: Detail Drawing by Auditorium Experts

Auditorium Experts excels in detail drawing services tailored for performance spaces, ensuring meticulous planning and precise execution of architectural and technical designs. Our expertise in creating comprehensive drawings sets the foundation for seamless project implementation and exceptional results.

Key Offerings

1. *Architectural Detailing Detailed drawings that encompass spatial layouts, structural components, and aesthetic features to bring designs to life.

2. *Technical Specifications Clear and precise documentation of technical systems, including lighting, acoustics, and audio-visual equipment integration.

3. *Construction Documentation Comprehensive plans and specifications that facilitate accurate construction and installation processes.

4. *Collaborative Design Review Interactive sessions to review and refine drawings in collaboration with clients, architects, and stakeholders.

5. *Quality Assurance Rigorous quality control to ensure compliance with industry standards and project requirements.

Why Choose Auditorium Experts?

- *Specialized Expertise Extensive experience in designing performance spaces, delivering detailed drawings that align with architectural and technical specifications.

- *Enhanced Communication Visual representations that facilitate clear communication and understanding among project stakeholders.

- *Efficiency and Accuracy Streamlined processes and meticulous attention to detail to ensure precise execution and project success.

- *Client-Centric Approach Tailored solutions that meet client objectives and preferences, fostering trust and satisfaction.

Elevate Your Performance Space

Partner with Auditorium Experts at Perfect Stage to transform your performance space visions into reality with precision and expertise in detail drawing services. Our commitment to excellence ensures that every aspect of your project is meticulously planned and executed. Contact us today to discuss how we can support your next project with our specialized expertise.

---

This blog post emphasizes Perfect Stages expertise in detail drawing services for performance spaces, highlighting our dedication to precision, collaboration, and meticulous planning to achieve outstanding architectural and technical designs.

Precision and Quality You Can Trust

The drawing details a high-quality mild steel part fabricated using advanced laser cutting methods. With a focus on dimensional accuracy, a surface roughness of Ra 1.6 m, and a durable zinc-plated finish, this component is perfect for assembly and fabrication purposes. The precise 2D CAD specification ensures each piece consistently meets the industry's stringent requirements, making it highly reliable for dealers and manufacturers alike.

Engineered for Versatile Applications

With a standard size of 80 x 50 x 3 mm and a silver zinc-plated finish, this part offers versatility across multiple sectors. Its robust mild steel composition and protective finish make it suitable for both indoor and outdoor applications. As a foundational component, it is ideal for use by fabricators, assemblers, and industry suppliers throughout India's vast manufacturing and distribution networks.

FAQ's of Detail Drawing:

Q: How is the mild steel part manufactured according to the detail drawing?

A: The part is produced using laser cutting technology, which delivers precise dimensions and clean edges, followed by zinc plating to enhance corrosion resistance and improve its silver appearance.Q: What is the benefit of the zinc-plated finish on this component?

A: The zinc plating provides excellent corrosion resistance, extending the part's lifespan and maintaining its aesthetic silver color, making it suitable for various environments and applications.Q: Where can this product be used within fabrication and assembly?

A: This mild steel component is designed for integration into broader fabrication and assembly projects, such as structural frameworks, machine assemblies, or custom builds, particularly within automotive, construction, and manufacturing industries.Q: When should this part be selected for a project?

A: This component is ideal when precise, durable, and corrosion-resistant parts are needed, especially where tight tolerances (0.1 mm) and a quality surface finish (Ra 1.6 m) are critical to the assembly.Q: What are the key specifications to consider during procurement?

A: Key specifications include its material (mild steel), finish (zinc plated), thickness (3 mm), dimensions (80 x 50 mm), surface roughness (Ra 1.6 m), weight (approx. 120 grams), and tolerance (0.1 mm).Q: How does the surface roughness Ra 1.6 m impact the application of the part?

A: A surface roughness of Ra 1.6 m ensures a smooth finish, which is beneficial for tight-fitting assemblies, reducing friction and enhancing the aesthetics of the completed product.Q: What process ensures the part meets dimensional accuracy?

A: Advanced laser cutting, guided by a 2D CAD drawing, guarantees dimensional accuracy and repeatability, meeting the specified tolerance of 0.1 mm.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free